- HOME

- ABOUT US

- PRODUCTS

-

-

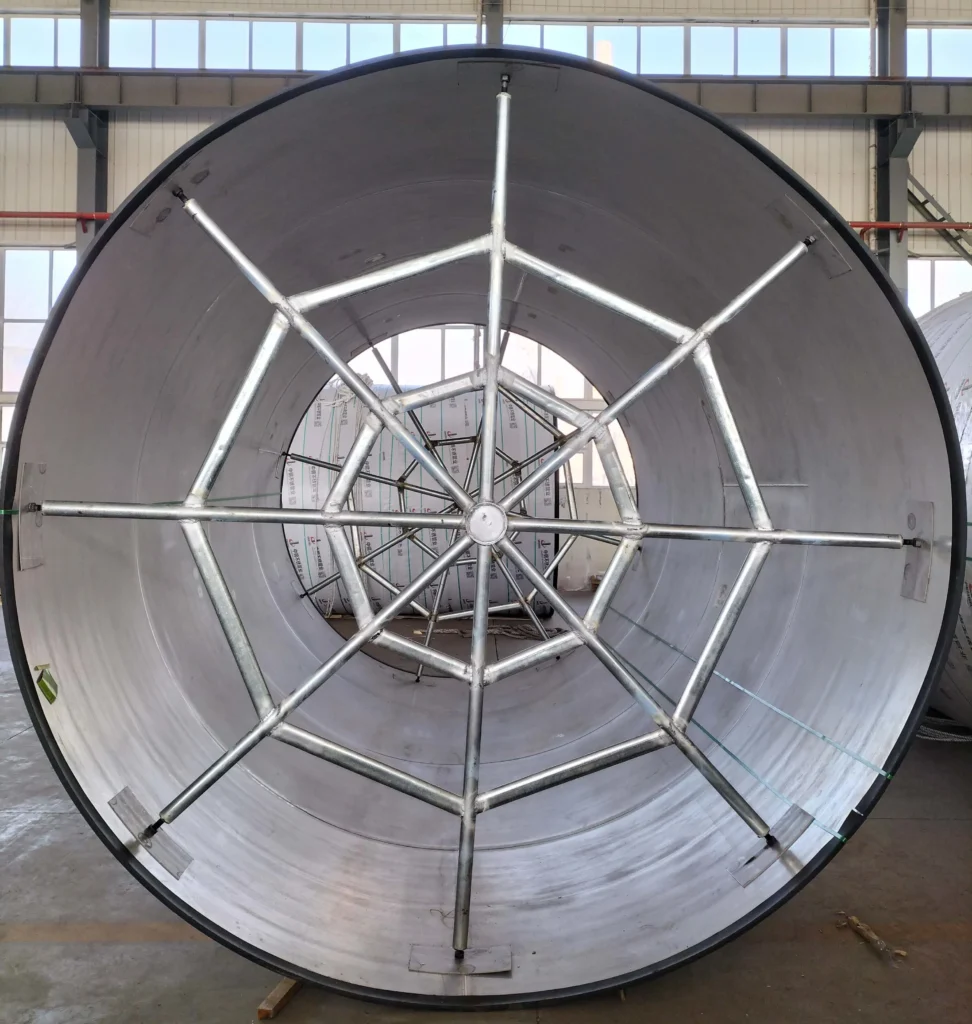

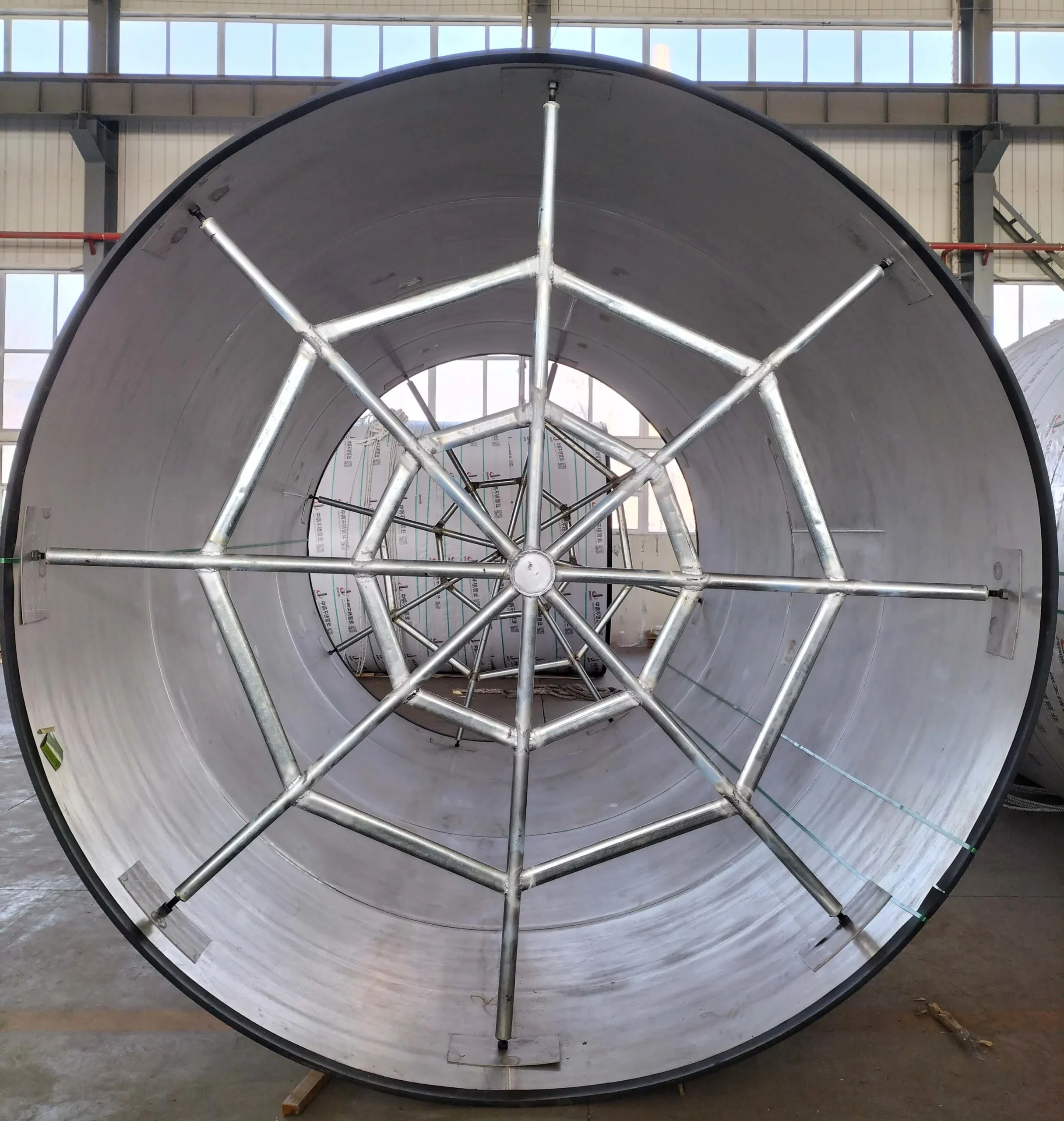

PRODUCTS

SINOSTEEL PIPE offers a wide range of products, including welded pipes, seamless pipes, pipe fittings, composite pipes, and other pipeline series. We also provide plate processing and steel coil slitting services to support pipeline needs.

-

-

- APPLICATION FIELD

-

-

APPLICATION FIELD

With the rapid development of the stainless steel pipe industry, it is becoming increasingly common in applications, including traditional energy, emerging energy, and high-end fields. SINOSTEEL PIPE provides the highest quality products for various stainless steel pipe application fields through advanced manufacturing and testing equipment and a strong technical research and development team!

-

-

- MATERIAL

- NEWS

-

-

NEWS

Take you into the SINOSTEEL PIPE to understand the latest corporate dynamics and news information.

-

-

-

- CONTACT US

- VR